GDQ-J-A Pneumatic High Vacuum Flapper Valve

Product Name: GDQ-J-A Series Normally Closed Pneumatic High Vacuum Flapper Valve

Category: High Vacuum Flapper Valve

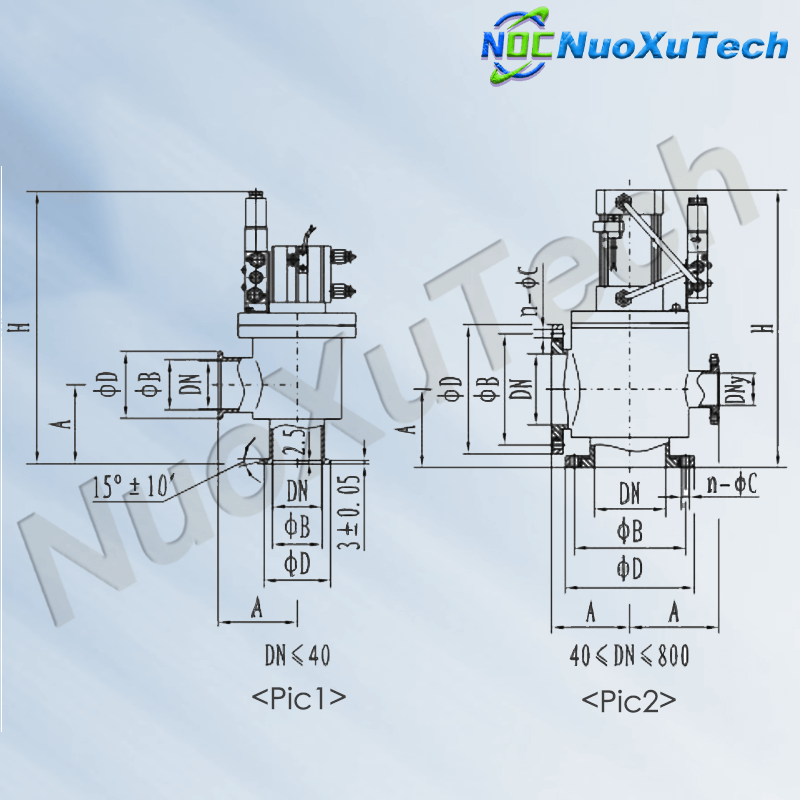

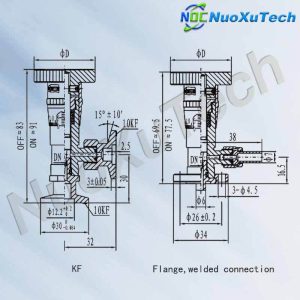

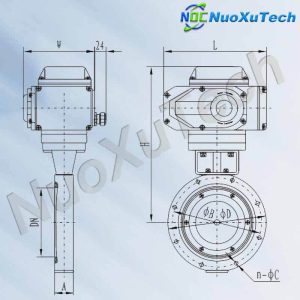

The GDQ-J-A Series Normally Closed Pneumatic High Vacuum Flapper Valve is engineered for precise control within vacuum systems. This valve utilizes an electromagnetic directional valve to control the valve plate opening and closing using compressed air. In the event of a power outage or loss of compressed air, valves with a nominal diameter (DN) of 80 or below will automatically close using spring force. For DN100 and above, the valve utilizes a solenoid valve group and a check valve to quickly close the original air source pressure, ensuring rapid shut-off.

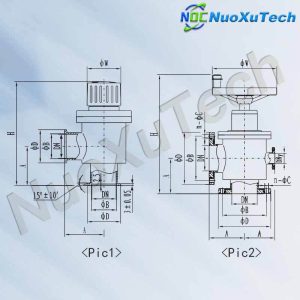

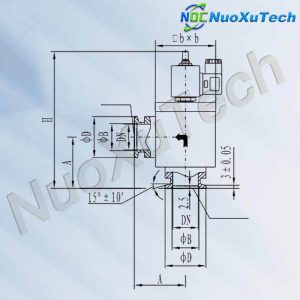

This series includes two types of shaft seal structures: the GDQ-J-A with rubber seals and the GDQ-J-A(b) with bellows seals. The GDQ-J type features an angle passage design, while the GDQ-S type includes a three-way design with a pre-extraction port. These design variations make the valve suitable for diverse applications within vacuum systems.

Key Features:

- Automatic Closure: Ensures rapid shut-off using spring force for DN80 and below, and a solenoid valve group for DN100 and above, providing reliable operation during power or air supply failure.

- Shaft Seal Options: Available with rubber seals (GDQ-J-A) or bellows seals (GDQ-J-A(b)) for enhanced flexibility and performance in different applications.

- Design Variants: Includes angle passage (GDQ-J) and three-way design with a pre-extraction port (GDQ-S) to meet various system requirements.

- Medium Compatibility: Suitable for air and non-corrosive gases, making it ideal for a wide range of vacuum applications.

Applications:

- High vacuum systems in industrial processes

- Semiconductor manufacturing

- Pharmaceutical production

- Chemical research and processing

- General laboratory vacuum applications

Technical Specifications:

- Operation: Pneumatic with electromagnetic directional control

- Automatic Closure: Spring force or solenoid valve group for rapid shut-off

- Shaft Seal Options: Rubber seals (GDQ-J-A) or bellows seals (GDQ-J-A(b))

- Design Variants: Angle passage (GDQ-J) and three-way design with pre-extraction port (GDQ-S)

- Working Medium: Air and non-corrosive gases

Advantages:

- Reliable Shut-Off: Ensures rapid and automatic shut-off to protect vacuum systems.

- Flexible Design: Multiple seal and design options to suit diverse applications.

- Durable Construction: Engineered for long-term reliability and performance in demanding environments.

- Versatile Application: Suitable for various industrial and research applications requiring high vacuum integrity.

For more information about the GDQ-J-A Pneumatic High Vacuum Flapper Valve, contact NuoXuTech

Keywords

vacuum system,nuoxutech, vacuum pump, VacuumSystem.