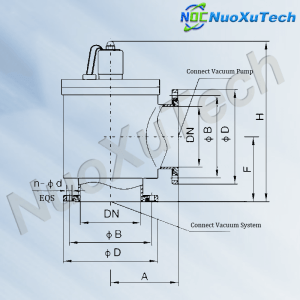

| Applicable Scope(Pa) | 2×105~1.3×10-4 |

| Valve Leak Rate(Pa.L/S) | ≤1.3×10-6 |

| Medium Temperature(℃) | -25~+80(Seal Material: chemigum) -30~+150(Seal Material: viton) |

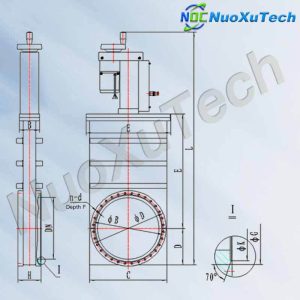

| Install Position | arbitrary |

Connection Forms:

- Lap Joint Flange Connection: Allows for secure and leak-tight connection using lap joint flanges.

- Fast Unload Flange Connection: Provides quick and easy installation and removal using fast unload flanges.

- Weld Type Connection:

- Weld I Type Connection (Both End Weld): Both ends of the valve are welded to the system, ensuring stability and integrity.

- Weld II Type Connection (One End Weld, Another End Insert): One end of the valve is welded to the system, while the other end is inserted, offering flexibility in installation.

Applications:

- Vacuum Systems: Used for cutting off or connecting vacuum systems in various industrial and scientific applications requiring high vacuum levels.

- Semiconductor Manufacturing: Ideal for semiconductor fabrication processes where precise vacuum control is crucial for ensuring product quality and yield.

- Thin Film Deposition: Suitable for thin film deposition techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD).

- Research and Development: Applied in research laboratories and experimental setups for creating controlled vacuum environments.

The GM High Vacuum Diaphragm Valve offers superior performance, leak-tight sealing, and versatile installation options, making it a reliable choice for high vacuum applications across different industries.

For more information about the GM series High-vacuum diaphragm valve, contact us

WhatsApp: +86 13849062209

Our team is ready to provide you with professional service and support.

Keywords

vacuum system,nuoxutech, vacuum pump, VacuumSystem, GM series High-vacuum diaphragm valve.